Metal Marvels: Advancing the Field of Metallurgical Testing Systems

Metallurgical testing is essential for verifying the quality, performance, and safety of metals across diverse industries, including aerospace, automotive, and construction.

Metallurgical testing is essential for verifying the quality, performance, and safety of metals across diverse industries, including aerospace, automotive, and construction.

Understanding Metallurgical Testing

1. The Importance of Metallurgical Testing

Metallurgical testing evaluates the physical and chemical properties of metals to ensure compliance with stringent standards. This process is critical for preventing product failures, ensuring safety, and maintaining long-term reliability in demanding applications.

2. Applications Across Industries

From aircraft and automotive manufacturing to infrastructure projects, metallurgical testing informs material selection, predicts durability, and ensures compliance with regulatory requirements. It provides actionable insights that guide engineering and design decisions.

Core Components of Metallurgical Testing Systems

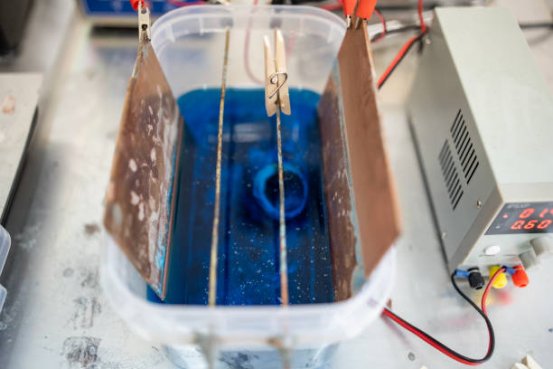

A comprehensive metallurgical testing setup includes specialized instruments for assessing metals’ structural and chemical properties. Typical systems feature spectrometers, tensile testing machines, polishing units, and additional laboratory equipment designed for precise analysis.

Key Types of Testing and Equipment

1. Spectrometer for Stainless Steel

Spectrometers accurately measure elemental composition, supporting alloy selection and quality verification. This technology is indispensable for maintaining consistency across production batches.

2. Metallurgical Analysis

Microscopy, hardness testing, and other analytical techniques reveal microstructure, ductility, strength, and wear resistance, offering a detailed understanding of metal performance.

3. Polishing Machines

Polishing machines prepare samples for microscopic examination, ensuring smooth, reflective surfaces for precise identification of flaws and microstructural features.

4. Laboratory Equipment

Advanced labs may include microscopes, furnaces, and hardness testers, enabling comprehensive testing of metallic materials.

5. Tensile Testing Machines

Tensile machines measure elasticity and strength under controlled loads, providing insights into how materials behave under stress until failure occurs.

6. Metallurgical Accounting

Tracking and analyzing material flow during production reduces waste, increases efficiency, and ensures accurate reporting for quality management.

7. Testing Services

Specialized metallurgical labs provide detailed analyses for quality control, research, and certification, helping companies maintain standards and enhance product performance.

8. Quality Control Practices

Ongoing testing and analysis ensure metals meet required specifications, with corrective actions applied promptly when deviations are detected.

Role of Metallurgical Testing Labs

1. Local Testing Facilities

Nearby labs offer rapid and reliable testing services, minimizing transport costs and turnaround time. They provide critical support, including failure investigations, quality verification, and material characterization.

2. MTS Metallurgical Testing Services

MTS delivers tailored testing solutions for aerospace, automotive, and construction industries, assessing durability, strength, and environmental resilience. Combining cutting-edge instruments with rigorous standards, MTS enhances safety and supports innovation.

Comparing Testing Equipment

| Equipment Type | Function | Key Features | Ideal Use |

| Spectrometer | Elemental composition analysis | High precision, rapid results | Quality control, material selection |

| Tensile Testing Machine | Measures tensile strength and elasticity | Controlled force application | R&D, mechanical testing |

| Polishing Machine | Prepares samples for microanalysis | Adjustable finish quality | Microstructure analysis, flaw detection |

Emerging Trends in Metallurgical Testing

1. Integration of Automation & AI

Automation enhances testing efficiency, reduces errors, and ensures consistent results, while AI enables predictive analysis and deeper insights from data.

2. Advancements in Non-Destructive Testing (NDT)

Ultrasonic, radiographic, and other NDT methods allow examination of material integrity without causing damage, improving both safety and workflow.

3. Sustainable Testing Solutions

Eco-friendly procedures and equipment minimize environmental impact while maintaining analytical precision and compliance with industry standards.

Frequently Asked Questions

What is the primary goal of metallurgical testing?

To confirm that metals comply with strict performance, safety, and quality standards.

How do spectrometers work?

They analyze the light spectrum emitted by metal samples to determine chemical composition with high accuracy.

Which industries rely on metallurgical testing?

Key sectors include aerospace, automotive, construction, and manufacturing.

Can tests be conducted on-site?

Certain evaluations are possible on-site, but most require specialized lab environments for accurate results.

Are learning resources available?

Yes, universities and industry organizations provide online training and certification programs for metallurgical techniques and equipment usage.

Conclusion

Metallurgical testing systems are indispensable for maintaining the quality, safety, and performance of metallic materials. The integration of automation, AI, and sustainable practices ensures faster, more reliable testing, supporting innovation and compliance across industries.

References

https://www.astm.org

https://www.iso.org

https://www.twi-global.com